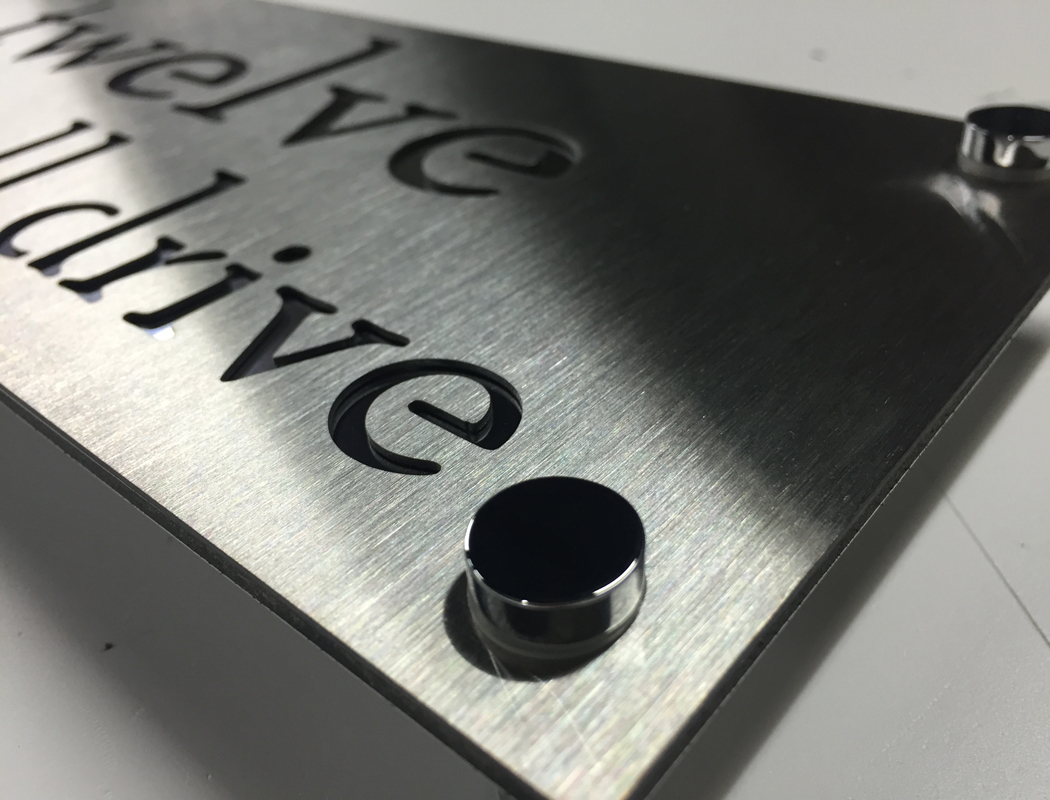

Stainless Steel Laser Cutting

Nitrogen assist gas leaves a clean dross free edge with minimal heat affected areas.

Stainless steel laser cutting. Kern s 400w co2 systems are capable of cutting up to 080 with. At stainless design we invest in industry leading laser cutting technology to process all grades of carbon mild steel aluminium and stainless steel from one off items through to large batch manufacturing using laser cutting machines that are second to none for accuracy quality and speed. Fractory uses state of the art fibre laser cutters to perform the job quickly. Stainless steel cutting needs the right kind of equipment and know how because of its reflective surface.

A computer directs this laser to follow the cutting line provided in your digital design. Some lend themselves really well to laser cutting technology while others fit better for plasma cutting. Austenitic stainless steel is one of the most commonly used steels in the construction industry. Laser cutting steel is a subtractive manufacturing technology that uses a high power laser beam to cut flat sheet materials.

The laser was first theorized by albert einstein in 1917 but it wasn t until 1960 when the first laser beam was created. Laser cutting stainless steel works with a wide variety of industries. The high precision laser vaporizes a cut line through the stainless steel leaving a 90 degree high quality cut edge finish. This results in less exposure to heat thus a burr free final product.

From custom signage to aerospace car parts and more stainless steel is our most popular metal cutting application. Types of stainless steel in relation to laser cutting.